ERP Compatibility

All Epicor® 9 Versions Database IndependentPricing

Please contact us for pricingDisclaimer

Epicor and Vantage are trademarks of Epicor.MES Serial Number Workflow

If you handle serialized parts and find that the standard Epicor® ERP methodology for assignment of serial numbers to conformance and non-conformance on End Operation is cumbersome then this solution could be for you. Utilizing a heavily customized End Labor Activity UI panel you’ll have visibility to all of the serialized units which have not been non-conformed from a previous operation and can easily designate which items do not pass muster. A reason code and notes can be quickly assigned to each serialized unit. When completed the standard non-conformance records are created for each serialized unit and the individual logged into the operation will be logged off the job.

Description

Video Demo

Where This Is Useful

This customization is most useful for companies who do serial number reporting at the operation level:

While this customization would have its greatest benefit if the site also utilized the Epicor® ERP quality functionality it will still have value for those sites who utilize other quality software.

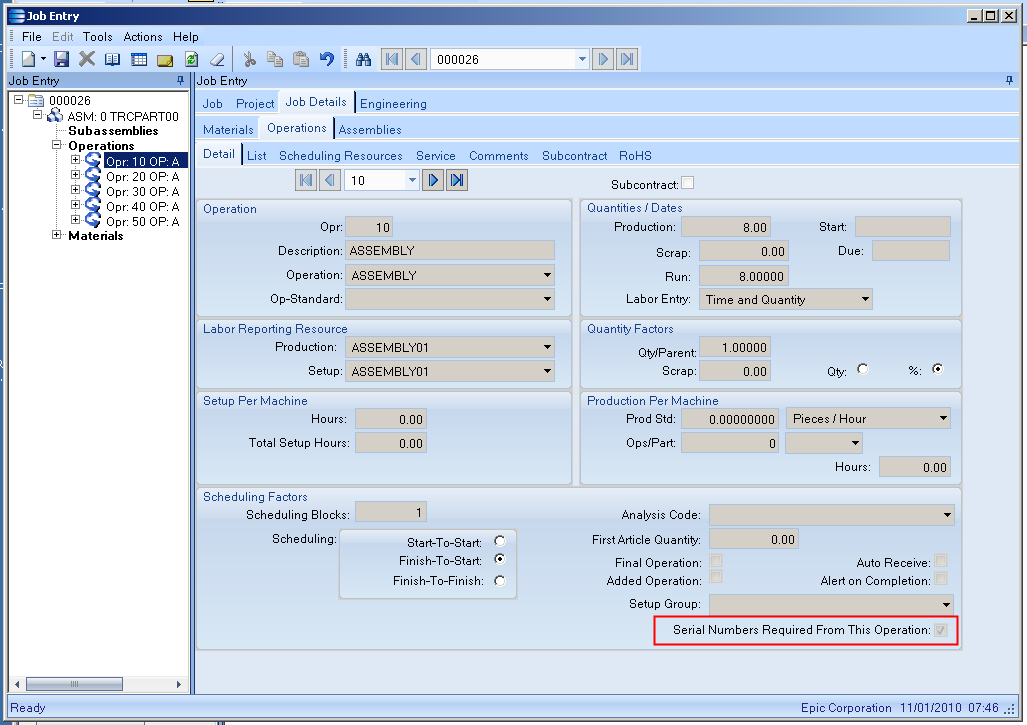

Standard Epicor® ERP Behavior

The default behavior in MES for serial number reporting at the operation level with quality integration is as follows:

- You clock onto the job / operation as normal within MES.

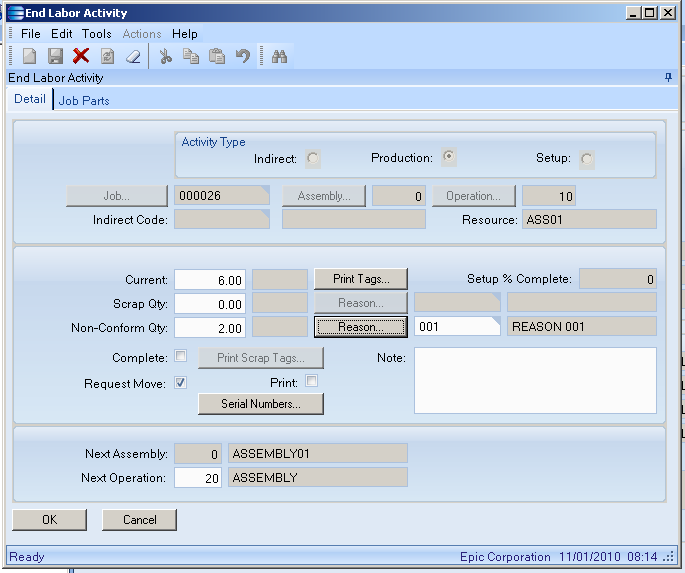

- When you are finished working on the job / operation, you click the End Activity button.

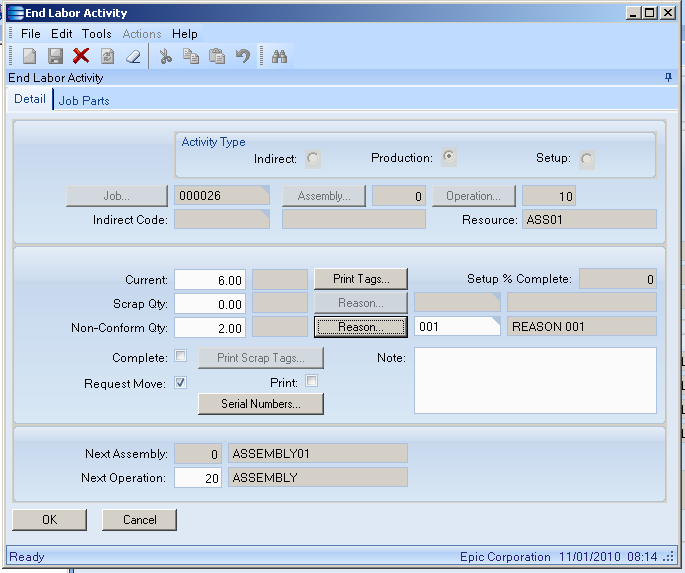

- Here you enter the good quantity in ‘Current’ and the non-conforming in ‘Non-Conform Qty’. You pick a single reason code for the entire non-conforming quantity (no way to tell it different reasons for different pieces).

- Next you need to go through some rather tedious steps to pick the serial numbers (even though they are already assigned to the job):

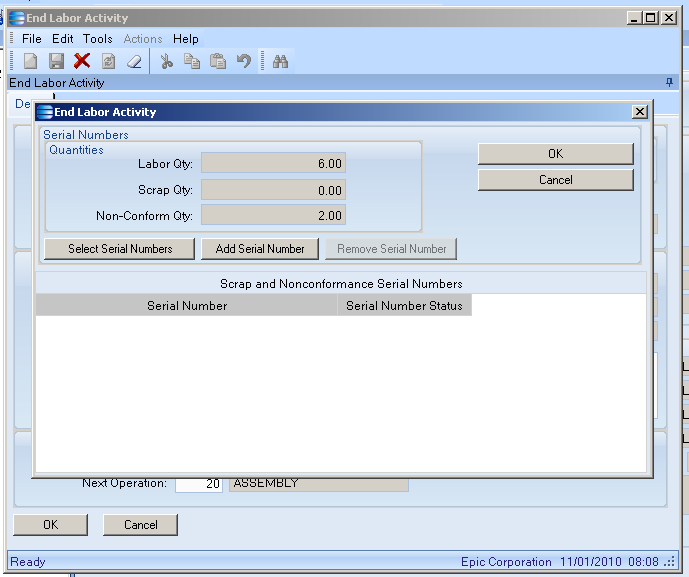

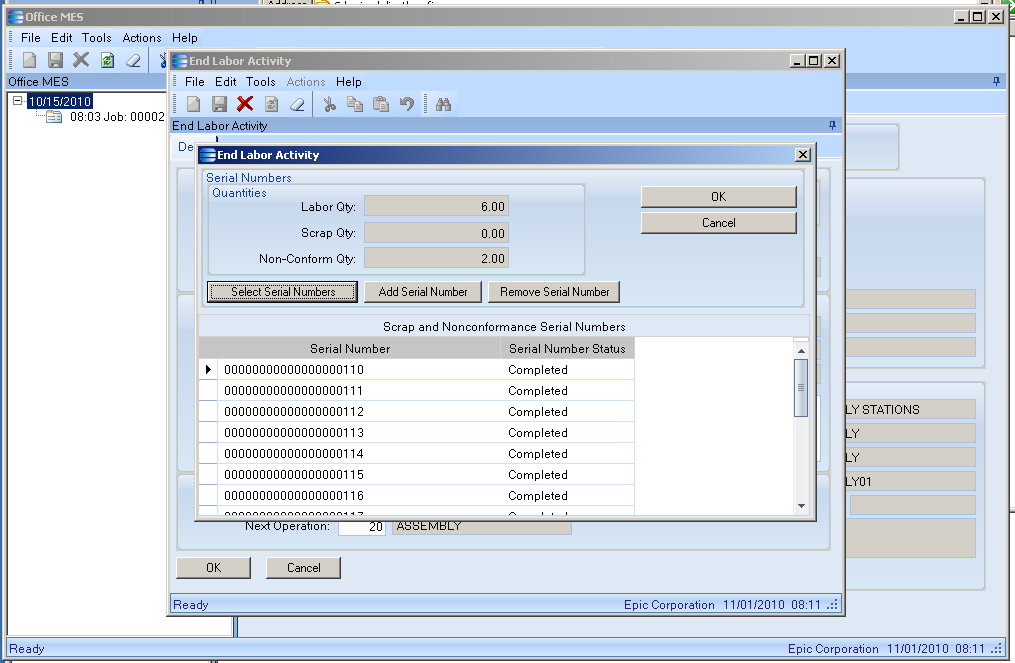

- Click the ‘Serial Numbers’ button:

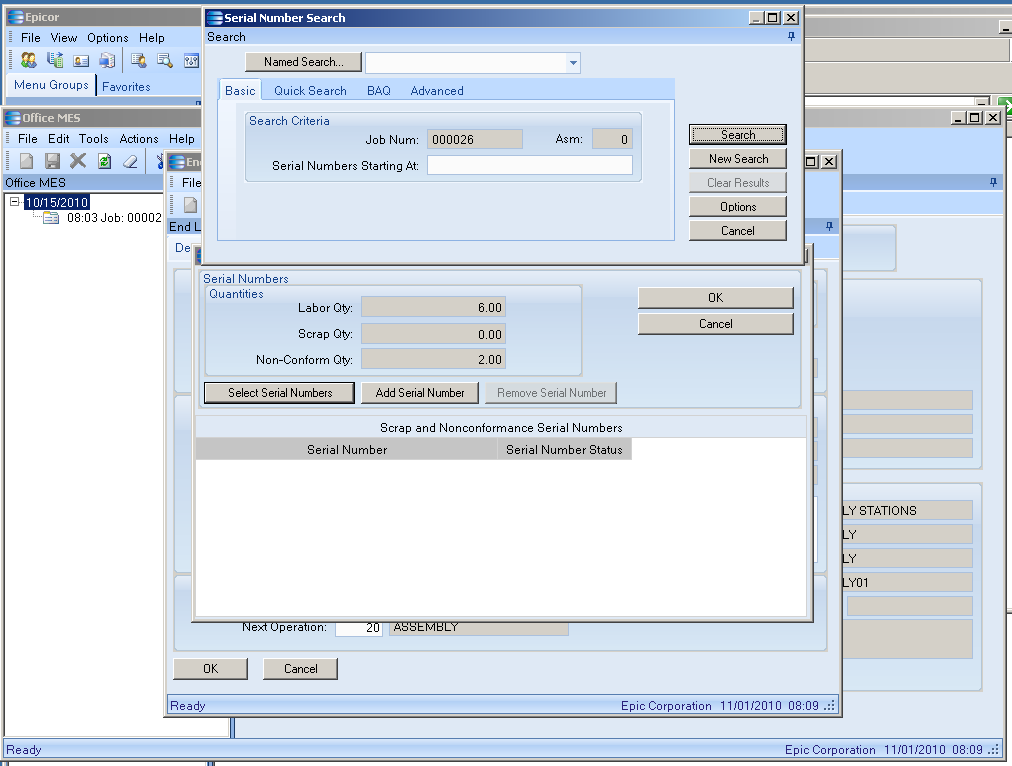

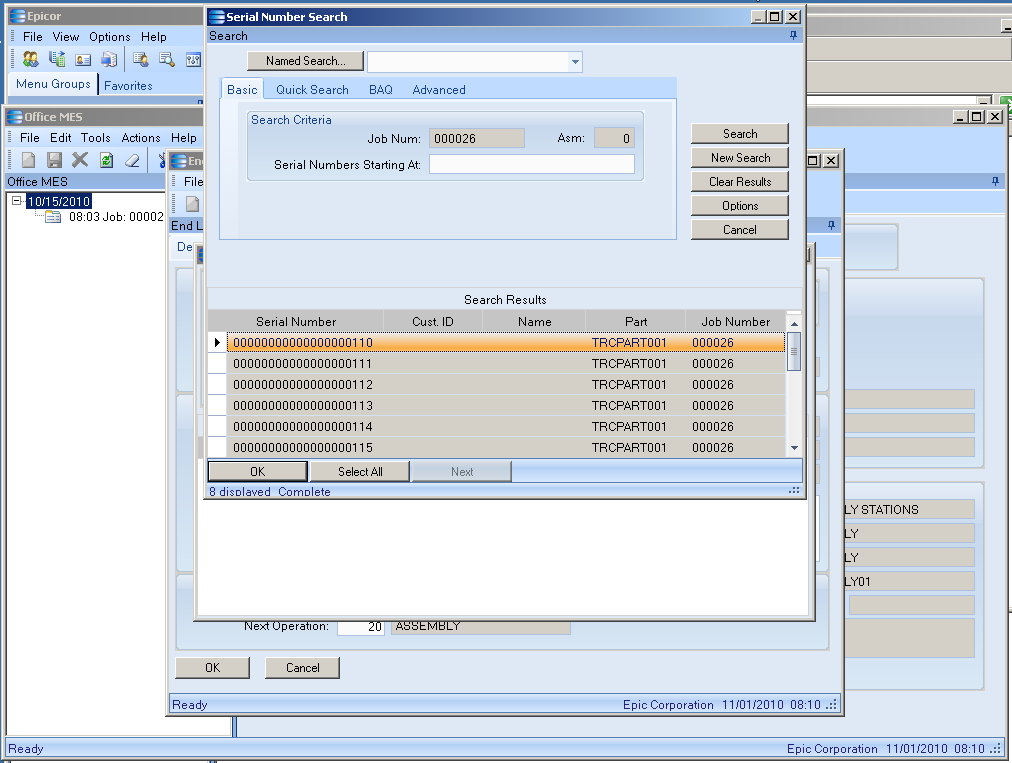

- Press ‘Select Serial Numbers’:

- Click ‘Search’:

- Press ‘Select All’ or select individual serial numbers (note: there is a bug on this screen that allows you to select serial numbers that were marked non-conforming at a previous operation – this customization resolves this issue).

- Pick the serial numbers that are non-conforming (you need to make sure that the quantity you select match the quantity that were specified on the end activity screen.

- Click ‘Ok’.

- Click ‘Ok’ again to log off the job.

Issues with Default Behavior

- It is a very tedious process to select the serial numbers.

- Only a single reason code can be selected for all non-conforming serial numbers. There is no way to tell it multiple reason codes.

- There is redundancy in the entering of quantities (you enter the quantities on the end activity screen but need to select the complete versus non-conforming serial numbers individually on the serial numbers screen.

Revised Behavior

The End Activity screen is heavily customized to address all of the negative issues with the default behavior:

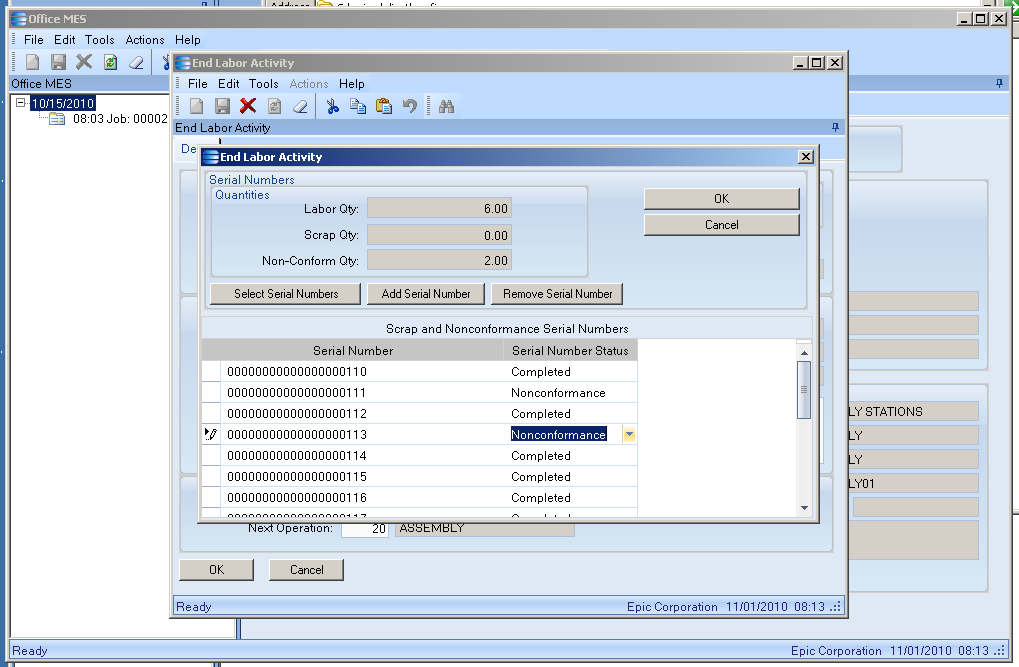

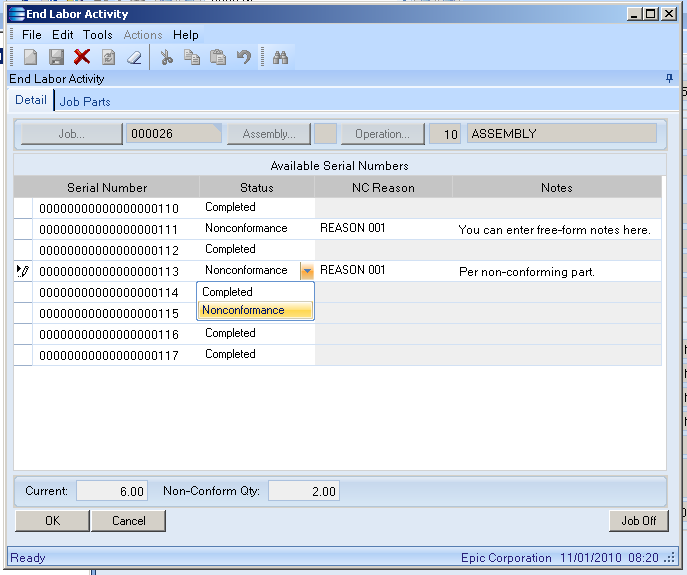

- The list of all serial numbers assigned to this job which have not been previously non-conformed at another operation will show up automatically in the grid.

- They automatically default to a status of ‘Completed’ but can be individually changed to ‘Nonconformance’ using the drop-down in that column.

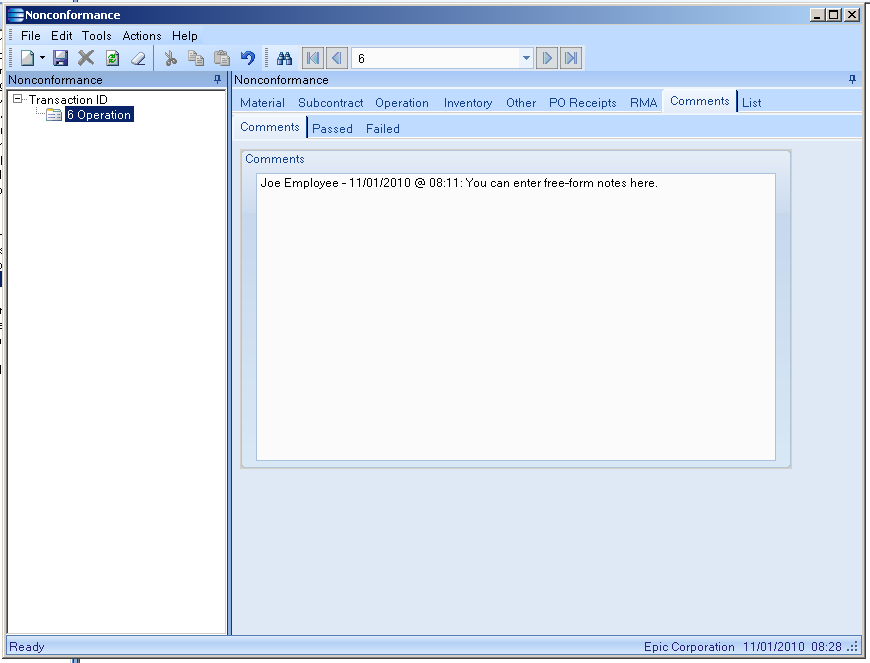

- Upon selecting a status of ‘Nonconformance’ the ‘NC Reason’ column is enabled for that row allowing you to select the non-conformance reason for that serial number. A notes column is also present to allow free-form notes to be associated with that specific serial number.

- The ‘Current’ and ‘Non-Conform Qty’ fields at the bottom of the screen are automatically calculated to avoid any need to duplicate data entry.

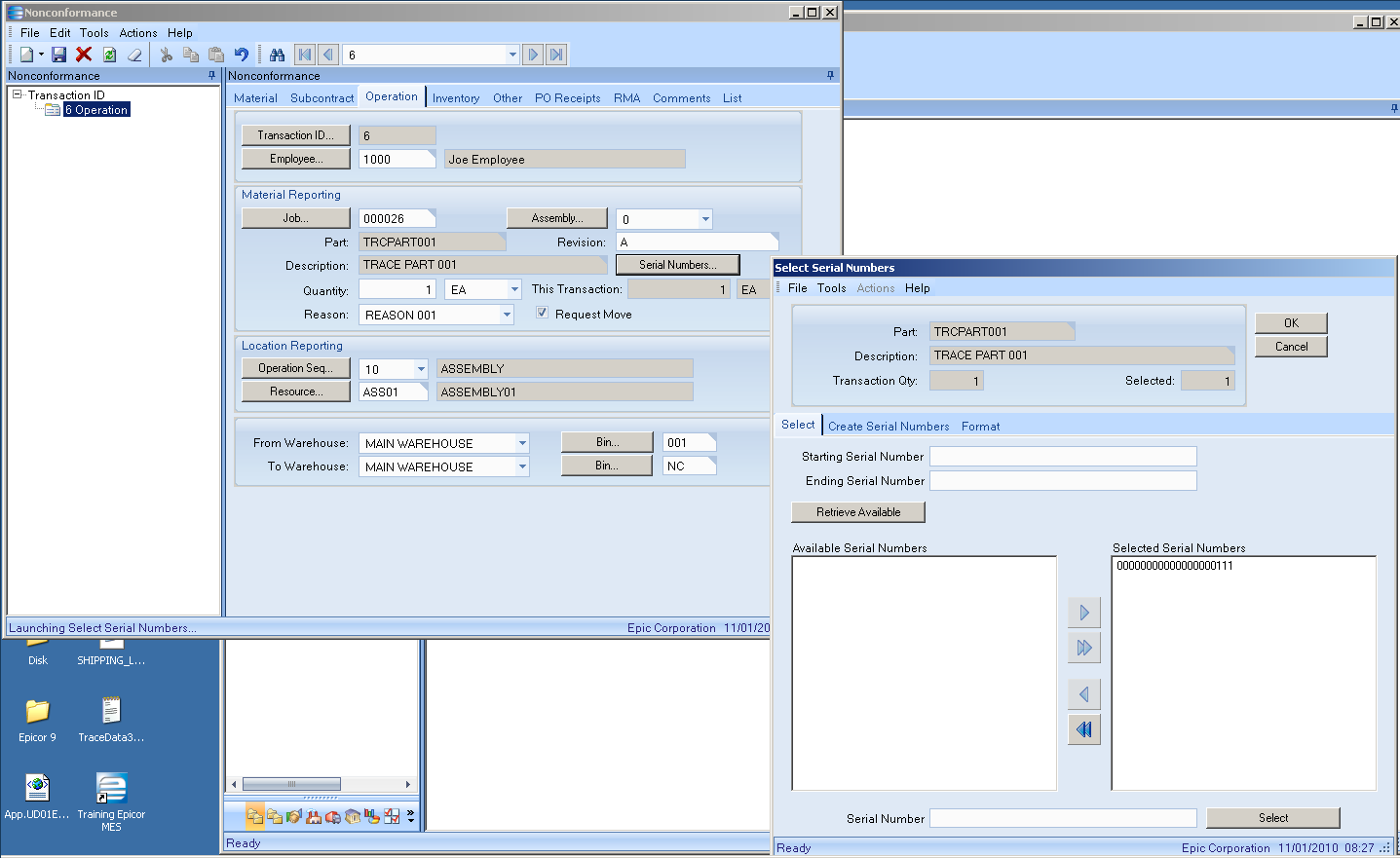

Upon clicking ‘Ok’ on this screen, you will be logged off the job and a unique non-conformance will be created per serial number in order to allow each to have its own reason code and notes:

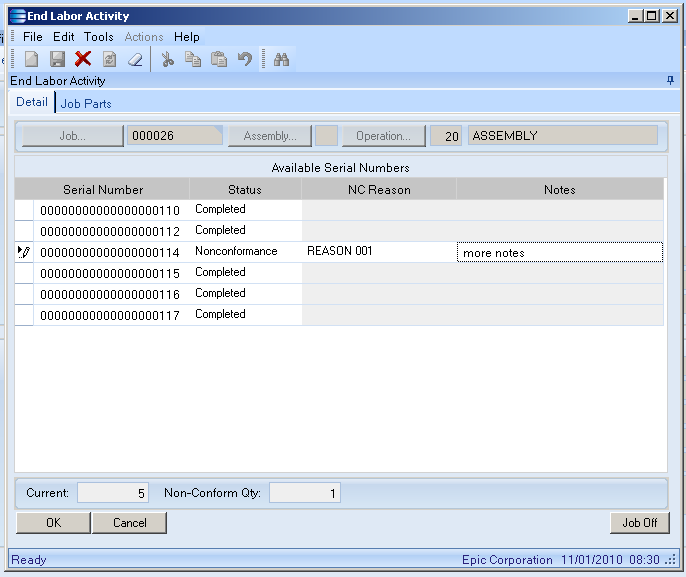

The serial numbers that were marked as ‘Complete’ can proceed to the next operation (upon selecting End Activity you will only see them):

Epicor and Vantage are registered trademarks of Epicor Software Corporation.