ERP Compatibility

Epicor® 8.03, 9.04 and 9.05 Database IndependentPricing

Please contact us for pricingDisclaimer

Epicor and Vantage are trademarks of Epicor.Consolidated Job Issue and Receipt

Implementing this custom solution will provide a consolidated workbench which can be used to issue material to a job, receive the finished goods to the warehouse, create the labor entries for the job, backflush material as appropriate and trigger the printing of label(s). If your finished goods parts are lot tracked they will automatically have the lot ID assigned as the job number; if they are serial tracked serial numbers will be auto-generated, assigned to the job, and associated with the inventory being received.

Description

Video Demo

A new menu item provides visibility to a new UI panel where the data capture and processing are controlled. Alternatively, this new UI panel can be structured to be called from a button on the MES menu if so desired.

The design of this solution is premised upon the use of scanning as the primary method of data entry and all that would be needed to support this processing methodology is to code your scanners to include a “line return” at the end of the barcode.

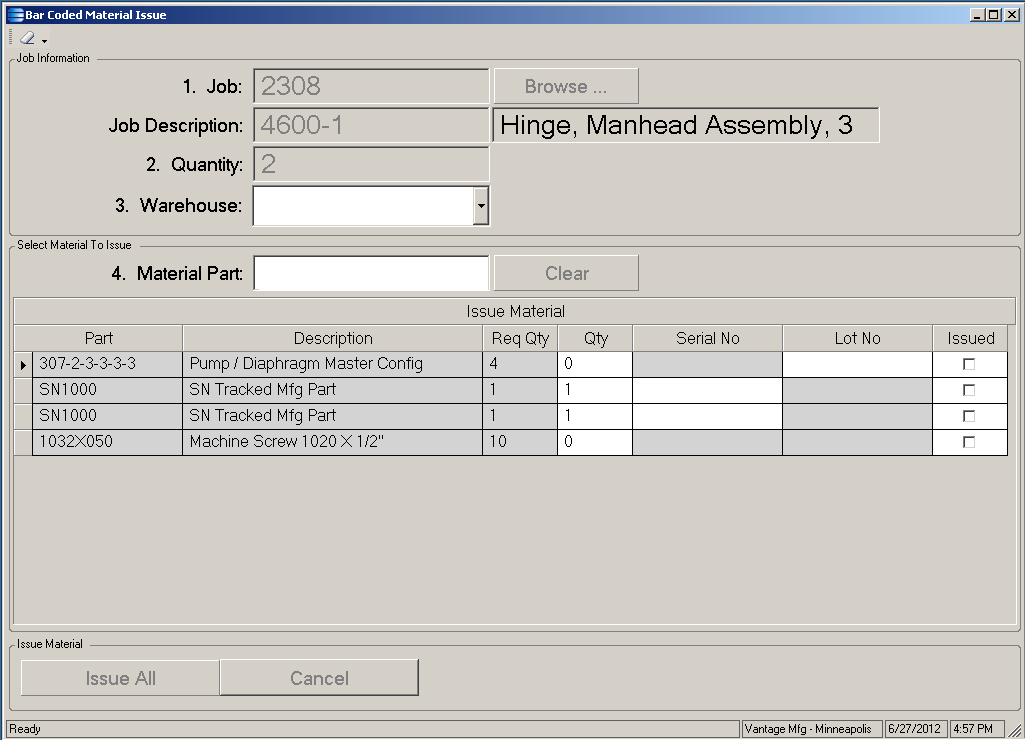

The process starts by entering or scanning in the job and the quantity completed.

As you can see above, all of the material components from the BOM for the job part will populate into a grid at the bottom of the main UI panel and a processing flow will be initiated. The “Req Qty” reflects the quantity needed for the entered completion quantity based upon the BOM quantity per.

Note the warehouse field. The solution is configured to skip over this field as it is not needed for issuing material. If however you want to restrict issuing of material from a specific warehouse you may optionally designate the warehouse utilizing this field.

The flow is again premised upon scanning of barcoded part numbers being the primary means of data entry and the field for “Material Part” is provided for this purpose. When a part number is scanned or entered control immediately jumps to the corresponding line in the grid for the part number. The Lot and Serial columns will be enabled/disabled according to the setup on the part. If the part is lot tracked then the lot column will be enabled and the serial column disabled for that part. If the part is neither lot nor serial tracked then both columns will be disabled. Processing will flow as below:

- Serial tracked part

- Quantity defaults to 1

- The serial number column is enabled and awaits entry of the serial number. Upon a valid scan (the serial number is validated in real time) the cursor will return to the ‘Material Part’ field without any keyboard / mouse intervention -or- the next serial number field for this part if present.

- There will be as many lines in the grid for the serialized part as the total required quantity for that part. In the example screen cap above you’ll note that there are two lines in the grid for part SN1000 as the BOM quantity to build two of job part 4600-1 is two.

- Lot tracked part

- The quantity can be scanned or keyed in. Upon hitting enter the focus (or end of scan) the focus will automatically move to the lot field. Upon a valid scan (the lot number is validated in real time) the cursor will return to the ‘Material Part’ field without any keyboard / mouse intervention –or- a new lot number line for this part if necessary (described next).

- If the total of entered quantity for the part does not equal the required quantity the line in the grid will be cloned into a new line and control immediately passes to that line to accept entry of a new lot number. This process repeats until all lots have been entered.

- “Standard” parts

- Enter quantity issued to the job

In all instances when entry of the grid line data is completed for the part control will pass back up to the Material Part field for entry of the next part number.

Upon completion of entry of the material component quantity issued the “Issue All” button is clicked and the job issue and receipt activities will take place.

- Validate that everything which is needed for processing has been entered.

- Issue materials to the job as specified in the grid.

- If the job part is serial tracked then assign serial numbers for inventory purposes.

- Complete the receipt to inventory. Apply lot / serial numbers to the receipts as necessary.

- Trigger the formatting and printing of any desired labels.

- Create the labor entries for each of the job operations.

- Backflush the material parts which are so designated for the job.

- Flag the job as “Completed” and “Closed” if appropriate.